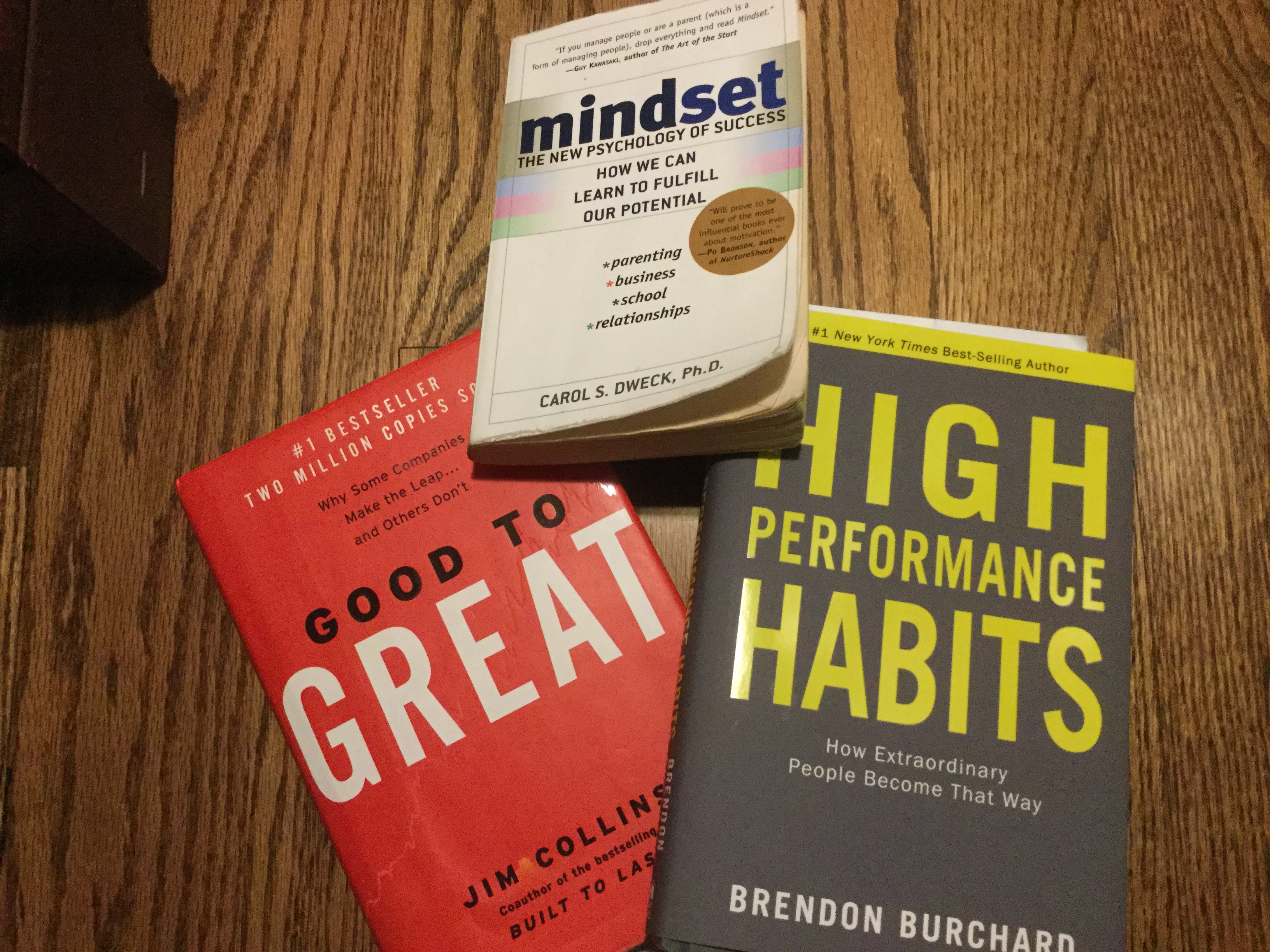

Terry’s Top Three Business & Mindset Books

Spring break is a great time to relax, recharge your batteries, and catch up on some reading. Three great business books that I highly recommend for your time on the beach include the the following classics: Mindset, by Carol Dweck, Good to Great, by Jim Collins, and High Performance Habits, by Brendon Burchard, where you …